Still have questions? You may want to look through our Frequently Asked Questions (FAQs) section to find answers to your questions. If you have a more specific question please feel free to call, whatsapp, live chat, e-mail or come by for a cup of coffee!

General FAQs

We were hoping you'd ask! Our application engineers are ‘engine specific’ school trained and would be happy to assist you in finding the right product for your application and process condition. Please get in touch! Our information hub is also a useful resource that can guide you in your product selection

You certainly can! We have been in the business since 1986. We run a quality establishment and our customers trust us to conduct business responsibly. Moreover, we are authorized full service distributors for most brands we carry.

Purchasing through an authorized distributor is the only way to ensure that:

- You are buying brand-new, authentic products

- Your product will be covered by factory warranty

- Any service or repair will be conducted by experienced professional

- You will experience the highest level of client service

There are several reasons why you should choose AYTC as your premier supplier of liquid, vapor & gas handling equipment.

- We represent only quality brands so you have can have confidence in what you're buying! Your business doesn’t stop when it gets hot, or when things get tough. Why should your equipment?

- Because of our high volume purchasing, we will in most cases, beat factory direct pricing.

- Every product we sell, whether it is a pump, meter or custom design skid, meets or exceeds safety and quality standards worldwide.

- Our application engineers have a wealth of industry knowledge and experience in fluid handling equipment. We are therefore able to assist in finding the right product or solution for your application in a way that promotes safety and compliance.

- Having lived and breathed the working of our products for over 30 years, there isn't much our technical team can't answer. Our exceptional after-sale support ensures any issues can be resolved quickly.

- We are authorised by manufacturers to honor warranty claims and repair / replace products on their behalf

- Our dedicated logistics team enable us to provide affordable and efficient delivery worldwide

No matter what you're looking for, whether it's equipment, skids & packages or complete turnkey solution, you can be sure you'll find it at AYTC. Browse our complete product range and place your order with us today!

We certainly do! In fact, we are authorised by most manufacturers to honor warranty claims and repair / replace products on their behalf.

Please review our General Terms & Conditions. Our equipment typically has a standard 1 year warranty against manufacturing defects. It does not cover issues caused by damage due to shipment, handling, storage, accident, impact, abuse or misuse. Specific product warranty information can be found on the product support pages

Although we do not anticipate any issues, please contact us if you are not 100% satisfied with the product and/or service you have received.

We believe customer satisfaction = repeat business and we hope we may have the pleasure of working with you for many years to come!

Yes we do! At Ali Yaqoob Trading Co. LLC, we endeavour to provide the best-in-class repair / service / refurbishment / reconditioning / overhauling your equipment can get. All equipment brought to our facility in Dubai (factory approved) undergo a very stringent inspection and an equally strenuous refurbishment/reconditioning process.

All service / repairs are performed by factory trained professionals. Additionally, to ensure the equipment we provide post service continues to serve our customers for at least another 10-15 years, we use only new, genuine parts manufactured in the last one year.

Absolutely! We have same day deliveries on most orders.

We deliver to your doorstep with our own fleet of vehicles anywhere in the U.A.E. We also ship internationally and will work with your preferred freight forwarder to get a shipment to you.

- Cash

- Check

- Bank Transfer

- Credit Cards

- MasterCard

- Visa

- American Express

- JCB

- Discover

- Paypal

- Apple Pay

- Samsung Pay

- Google Pay

We're open from 8:30am - 6pm (Sat - Thu)

Feel free to call, whatsapp, live chat, e-mail or come by for a cup of coffee!

Flow Meters

Flow meters are devices that measure the flow of a fluid traveling past a fixed point per unit time. No two flow meters are the same, and each type is better suited for different applications.

As specialists in flow meters in UAE, we supply rugged corrosion-resistant meters that are durable and suited for even the most demanding applications. Incredible utility, visual clarity, and amazing accuracy are what you can expect from our line of flow meters.

Please answer the following questions and we’ll point you to the meter that is best suited for your application and process conditions:

- What size / capacity are you looking for?

- What is the min/ max flow rate required?

- What is the product being handled?

- Do you require electronic or mechanical?

- Also, do you require any accessories such as strainer, air eliminator, preset valve, printer, etc.?

Alternatively, please send us a photo of the name plate / specifications or call us and one of our application engineers will be happy to assist you.

No. Meters are never calibrated at the factory as calibrating a new meter prior to installing it in your system does not serve any purpose.

All our Liquid Controls meters, Fill-Rite meters, Nitto Seiko Meters and B Meters are tested at the factory for repeatability & to ensure they comply with published accuracy specifications. These meters are supplied with a factory test certificate. This certificate does not have a validity or expiration date as it is not possible to define general rules for the required frequency of calibration.

However, it is always recommended to calibrate the meter under actual flow conditions, with the actual product being used, at the actual flow-rate to adjust for zero error. This is true of all flowmeters, irrespective of make/model.

We therefore recommend calibrating the meter at your site through a third party calibration company that is approved by Weights & Measures.

If operated under good working conditions, our meters do not require periodic re-calibration nor should they need to be re-calibrated over the operational life of the meter.

However, good working condition is a matter of proper use and maintenance. Some meters may experience an accuracy drift over time due to environmental or application related factors. If a meter is suspected to have drifted outside of its published accuracy range, it can be sent back to us for local third party calibration.

For most applications however, it is the relevant Weights & Measures local authority or the client/user who must define the calibration interval and the policy to determine when to calibrate.

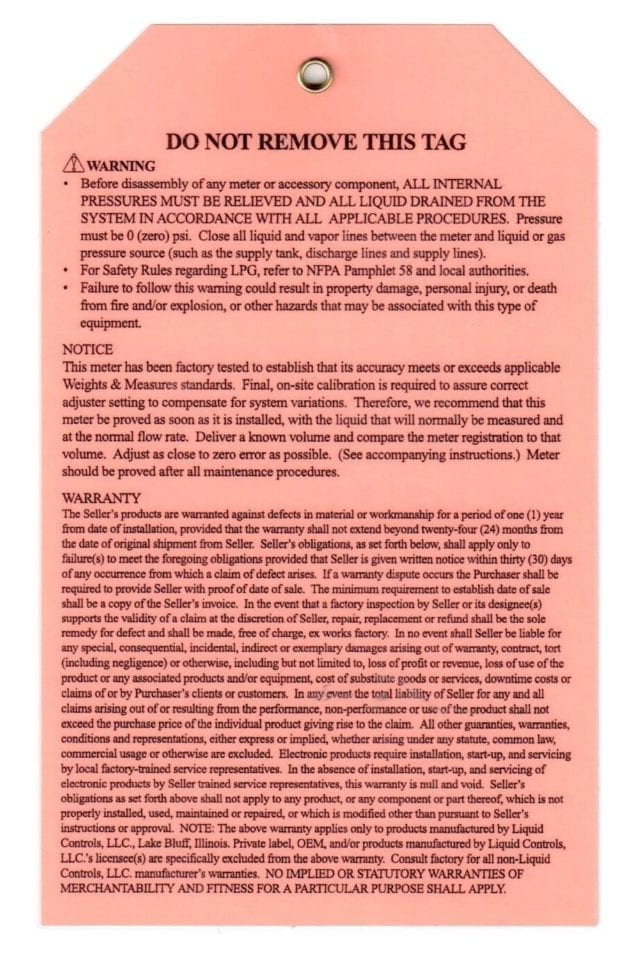

For this reason, every LC meter is supplied with a RED WARNING TAG, as per below sample, which states the above principle.

Please refer to the meter class of construction below to choose the right meter for your application:

| Class 1 | Refined petroleum products, such as leaded and unleaded gasoline, fuel oils, diesel fuel, kerosene, and ethylene glycol (antifreeze) and propylene glycol. Also used on motor oils, crop oils and rotogravure ink at reduced rates of flow. |

| Class 2 | Aviation gasoline and jet fuels |

| Class 3 | Variety of products such as: liquid sugars, corn syrup, corn sweeteners, dextrose, fructose, sucrose maltose, lactose, corn oil, soy bean oil, cotton seed oil, coconut oil and shortening's etc. |

| Class 4 | Treated waters and certain solvents where no red metals are allowed. |

| Class 7 | Chlorinated solvents such as: perchloroethylene, trichloroethylene, trichloroethane and methlyene chloride. Also used for general solvent service. |

| Class 8 | Acid pH liquids such as: nitric, phosphoric, glacial acetic acids, citric (fruit juices) and vinegars. |

| Class 10 | Liquefied petroleum gas (LPG) including butane, isobutane, pentane, ethane, freons, and propane. |

| Class 12 | Anhydrous ammonia (NH3). |

| Class 14 | Crude oil. For heated and/or viscous liquids including animal fats, resins, #6 oil and non-abrasive asphalt emulsions. |

| Class 15 | Oil or water based latex products, polyester resins, adhesives, herbicides, nitrogen fertilizers. |

| Class 16 | General solvent metering service such as: methanol, toluene, xylene, naphtha, acetone, MEK, MIBK, and alcohols including ethanol (also 200-proof alcohol). Class 7 meters should be used if the application involves the use of chlorinated solvents |

| Class 20 | Batch process water meter service. May be used for solvents and other liquids compatible with brass. |

| Class 27 | Alkaline pH liquids: latex products, adhesives, some liquid fertilizers (10-34-0). |

| Class 30 | Herbicides such as such as Aatrex, Atrazine, Bicep, Bladex, Dual, Lasso, Lasso ME, Treflan, Sutan, Sutazine, and Eradicane (requires PTFE seals). |

| Class 37 | Sodium hydroxide (caustic) solutions, high sulfur crude oil (LACT and NOD), and other alkaline pH liquids including non-abrasive asphalt emulsions, liquid feed (molasses) supplements, and some resins. Construction suitable for heated and/or viscous liquids. |

| Class 47 | Mildly abrasive liquids. |

Please see range and specifications of each meter model below.

|

M-Series |

Model |

Flange Size |

Nominal Flow Rate Range |

Maximum Pressure |

|||

|

Inches |

GPM |

LPM |

PSI |

BAR |

kPa |

||

|

M-5 |

1.5 |

6-60 |

22-227 |

150 |

10.3 |

1034 |

|

|

M-7 |

2 |

10-100 |

20-378 |

150 |

10.3 |

1034 |

|

|

M-10 |

2 |

15-150 |

56-567 |

150 |

10.3 |

1034 |

|

|

M-15 |

3 |

20-200 |

75-756 |

150 |

10.3 |

1034 |

|

|

M-25 |

3 |

30-300 |

110-1134 |

150 |

10.3 |

1034 |

|

|

M-30 |

4 |

35-350 |

132-1323 |

150 |

10.3 |

1034 |

|

|

M-40 |

4 |

45-450 |

170-1701 |

150 |

10.3 |

1034 |

|

|

M-60AVI |

4 |

45-600 |

170-2268 |

150 |

10.3 |

1034 |

|

|

M-60 |

4 |

60-600 |

225-2268 |

150 |

10.3 |

1034 |

|

|

M-80 |

6 |

80-1000 |

300-3024 |

150 |

10.3 |

1034 |

|

|

MA Series |

Model |

Flange Size |

Nominal Flow Rate Range |

Maximum Pressure |

|||

|

Inches |

GPM |

LPM |

PSI |

BAR |

kPa |

||

|

MA-4 |

1.5 |

6-60 |

22-227 |

150 |

10.3 |

1034 |

|

|

MA-5 |

2 |

10-100 |

20-378 |

150 |

10.3 |

1034 |

|

|

MA-7 |

2 |

10-100 |

20-378 |

150 |

10.3 |

1034 |

|

|

MA-15 |

3 |

20-200 |

75-756 |

150 |

10.3 |

1034 |

|

|

MSA-Series |

Model |

Flange Size |

Nominal Flow Rate Range |

Maximum Pressure |

|||

|

Inches |

GPM |

LPM |

PSI |

BAR |

kPa |

||

|

MSA-30 |

3 |

35-350 |

132-1325 |

300 |

20.7 |

2068 |

|

|

MSA-75 |

4 |

70-700 |

265-2650 |

300 |

20.7 |

2068 |

|

|

MSAA- Series |

Model |

Flange Size |

Nominal Flow Rate Range |

Maximum Pressure |

|||

|

Inches |

GPM |

LPM |

PSI |

BAR |

kPa |

||

|

MSAA-30 |

3 |

35-350 |

132-1325 |

285 |

19.7 |

1965 |

|

|

MSAA-40 |

3 |

45-450 |

170-1703 |

285 |

19.7 |

1965 |

|

|

MSAA-75 |

4 |

70-700 |

265-2650 |

285 |

19.7 |

1965 |

|

|

MSAA-120 |

6 |

100-1000 |

378-3785 |

285 |

19.7 |

1965 |

|

Pumps

Please answer the following questions and we’ll point you to the pump that is best suited for your application and process conditions:

- What is chemical composition or common name of the process liquid?

- Specific Gravity of the liquid?

- Maximum viscosity?

- Type of Duty (intermittent or continuous)?

- Supply Tank (underground or above ground)?

- Application (cylinder filling, bulk transfer, truck pump, autogas, other)?

- Pumping Temperature?

- Inlet pressure?

- Outlet pressure?

- Differential pressure?

- Required flow rate (in lpm or gpm)?

- Net positive suction head (NPSH) available

- Do you require a pump only, or complete pump set with motor, baseplate, coupling, etc.?

- If motor, ex proof or non-ex proof?

- Direct drive or V-belt drive w/ gear reducer?

Alternatively, please send us a photo of the name plate / specifications or call us and one of our application engineers will be happy to assist you.

Pumps should never be run dry. Damage to blades / vanes, impeller, bearings and wear plates will result.

Side channel pumps fill the hydraulic performance void between positive displacement pumps and centrifugal pumps. Since the impeller makes regenerative passes through the liquid, it is similar to a regenerative turbine. However, the actual design of the impeller and casing and the principles of operation differ greatly. The corresponding pressure increase (pump head) equals 5 to 10 times the amount generated by a similar size centrifugal pump at the same RPM.

Unlike other pump designs, the side channel pump can accommodate the transfer of liquid and gas mixtures with up to 50% entrained gas. This feature greater reduces the possibility air or vapor locking that can occur in other pump designs. A special suction impeller lowers the NPSH requirement for the pump. Ali Yaqoob Trading offers several models of side channel pumps for wide range of differential pressures and capacities.

BEP stands for Best Efficiency Point; it indicates the pump's optimal performance. Your pump should always be operating within +/- 10% of BEP on your pump's performance curve. Operating outside of that range can cause numerous issues including reducing your mechanical seal and bearing life as well as increasing cavitation in your pump. Learn how to calculate your pump’s performance, and get it operating within its BEP to increase your system’s efficiency!

Connect with one of our pump experts for help with the purchasing and repairs of your mission critical equipment. Our staff is trained to work with all types and brands of pumps. We offer high-level technical support to provide you with the best cost-saving solutions possible.

Dry Break Couplings

Todo dry break couplings are available in Aluminum, Gunmetal, & Stainless steel.

Please help us with answers to the following questions and we’ll point you to the Dry Break coupling that is best suited for your application and process conditions:

- What is the liquid / vapor / gas being handled?

- Do you require a tank unit (male) or hose unit (female) coupling?

- What is the line size?

- What is the temperature and pressure?

- End connections required: flanged or threaded? If threaded NPT or BSP? If flanged, spec of flange” #1150 or DIN?

Alternatively, please send us the specifications or call us and one of our Application Engineers will be happy to assist you.

Buna, Viton , PTFE and many more

Hose Reels

Todo dry break couplings are available in Aluminum, Gunmetal, & Stainless steel.

- Hose reels make hose handling safer and more efficient.

- Your hoses, cables and cords will last up to five times longer.

- You will improve hose management, which decreases labor costs.

- Your chances of injuries from tripping hazards will decrease.

- You also save the expense and time to replace expensive hoses that get run over by vehicles.

We have the widest range of hose reels, cord reels and cable reels for industrial, commercial and professional applications.